The West Country Mining Industry

Mining before 1780

The intrusion of the granite masses of the West Country into the sedimentary rocks led to extensive metamorphism and mineralization. There is archeological evidence for alluvial mining for copper, tin and other metals in Cornwall and Devon as early as c.2,150 BC. These metals were traded with Europe and the Mediterranean from at least as early as 500 BC. Production continued, mainly in Cornwall, up to c.1780, when there was a significant increase. However, there are very sparse mentions in the parish records of MORCOMBEs being employed in mining before c.1780. Even in Gwennap, we cannot prove how many MORCOMs in the area, between the 1600s and 1780, were engaged in mining or farming, though the increased movement of families to the area after c.1720 suggests the availability of a more profitable form of employment than being an agricultural labourer.

Mining 1780-1900

Early in this period, the Wheal Maid valley in Gwennap, and specifically Consolidated Mines, between St Day and Carharrack, were described by contemporary writers as "the richest square mile on earth". The Consolidated Mines were expanded rapidly after John Taylor, the speculator and engineer, took over in 1818, and turned the site into one of the most productive copper mines the world had seen. The underground workings extended for 63 miles and employed a work force of over 3,000. (NB Compare this with the peak 1841 population of Gwennap parish which was 10,794. Consolidated Mines ceased working in 1857 and, in 1861, amalgamated with neighbouring mines as Clifford Amalgamated Mines which continued, unprofitably, until 1870. Even during the peak of the mining boom, many small entrepreneurs failed along with their mines. However fortunes could be made as illustrated by John WILLIAMS , who at one stage owned nine out of every ten mines in the Gwennap area, employed over 100 mine captains, and built Scorrier House with the profits. His three sons expanded into copper smelting, foundries, harbours and banking, as well as owning some of the finest homes in the parish

Other major mining centres in Cornwall were Redruth, Camborne, Illogan, St Agnes, St Just in Penwith, Wendron, Linkinhorne, and the clay mining area near St Austell, which also had nearby copper and tin mines. The Tamar Valley, between Cornwall and Devon, nearby Tavistock, and Coombe Martin on the North Devon coast were also important. Many of the MORCOM/BE miners worked in these areas, but others were employed in the smaller clusters of mines which were scattered throughout the West Country. The decline of the mining industry and its effects will be discussed in the section entitled "Why did so many MORCOM/BEs leave the West Country?"

Some MORCOMs, and the majority of the 19th century MOR[E]COMBEs, were farm labourers, or occupied in other rural trades including quarry workers, smiths and shoe makers. Very few MORCOM/BEs were engaged in another major South Western occupation - fishing.

Cornish Mining World Heritage Site

There are sixteen UNESCO World Heritage Sites in England. Only three of these are industrial sites: The Iron Bridge Gorge, The Derwent Valley mills, and, in 2006, the Cornish Mining site, which was, in fact, ten historically significant mining areas in Cornwall, and also in West Devon

UNESCO's reasons for choosing Cornwall are described as follows in their web site:

"Much of the landscape of Cornwall and West Devon was transformed in the 18th and early 19th centuries as a result of the rapid growth of pioneering copper and tin mining. Its deep underground mines, engine houses, foundries, new towns, smallholdings, ports and harbours, and their ancillary industries together reflect prolific innovation which, in the early 19th century, enabled the region to produce two-thirds of the world’s supply of copper. The substantial remains are a testimony to the contribution Cornwall and West Devon made to the Industrial Revolution in the rest of Britain and to the fundamental influence the area had on the mining world at large. Cornish technology embodied in engines, engine houses and mining equipment was exported around the world. Cornwall and West Devon were the heartland from which mining technology rapidly spread".

The Gwennap-Chacewater mining district

Map of the Gwennap area which covers approx. 4 1/2 miles N. to S. and 2 1/2 miles W.to E.. Places in the database which are associated with the MORCOMs are underlined in red. ©Crown Copyright. Reproduced by permission of Ordnance Survey

Why emphasize this mining area?

This Gwennap-Chacewater district has been singled out for more detailed discussion, not only because of its prominence in the history of copper and tin mining, but for its importance to our one-name study. Even if we ignore the unnamed families with less than 50 individuals, over a third of all MORCOMs and close relations, listed in our database, had family roots in the Gwennap and Chacewater parishes. At the peak of Cornish mining a quarter of the male population was employed in the industry. Presumably, in Gwennap, one of the major centres of the industry, an even larger proportion of working men and boys must have been involved. One estimate is that there were about 7,000 employed in 23 Gwennap parish mines in 1819. Between 1823 and 1832 Gwennap parish accounted for almost one third of the total British production of copper.

Remains of Wheal Maid, part of Consolidated Mines, near St Day. ©Tony ATKIN

Two of our families are particularly numerous in this local history. The descendants and close relations of Hercules MORCOM (06458) and Margaretta, who married in Gwennap in 1666, number 2,554 individuals worldwide, but with few exceptions their ancestors remained in Gwennap and neighbouring parishes until the mid 19th century. Although the descendants of John MORCOMB and Grace PIERCE who married in St Issey in 1615, remained in that parish for about a century, a number of family members moved to Gwennap c.1720 (probably following the introduction of copper mining c.1700), and their descendants total about 3,500. Tracing families in the parishes is complicated by the frequency that we find as many as three couples with identical Christian names (e.g. William and Elizabeth MORCOM) having children in the same decades. This largely accounts for the number of relatively small "stray" families worldwide, who also originate from this area.

Technical Innovation in Gwennap

The greatest hazard of deep mining in Gwennap and elsewhere was flooding of the workings. The parish was in the lead for the two major inventions to address this ever present threat. A pre-Industrial era innovation was the Great County Adit begun in 1748 at Poldice by John WILLIAMS of Scorrier and eventually reached a length of over 40 miles of underground tunnel, providing drainage to over 100 mines at an average depth of 80-100m

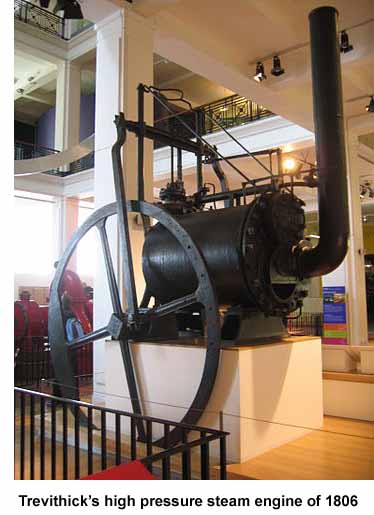

The introduction of beam steam engines, which were more efficient than the earlier Newcomen engines, allowed water to be removed from mines at a far greater depth. This development put the West Country mines, and, most of all those in Gwennap and neighbouring parishes, at the forefront of the Industrial Revolution. The engines were also used for winding men and ore up shafts, and for crushing ore. Matthew BOULTON and James WATT resided in Gwennap and Chacewater for long periods during the 1780s and 1790s, supervising the installation of their revolutionary engines, while William MURDOCH later joined them, making further valuable technical improvements. After the lapse of the Boulton and Watt patents in 1800, other local engineers, including Jonathan HORNBLOWER and Richard TREVITHICK (the true inventor of the locomotive in 1804), introduced more refinements. The greatly increased output of mines, equipped with steam engines, enabled the West Country mining industry to satisfy the rapidly expanding market for copper and tin in the UK and overseas. One writer judged that "by 1850 Cornishmen had more experience of deep mining, and with it deep pumping, than the rest of the world put together." Miners who had gained experience using these early steam engines, found that their skills were in demand in every deep mining area at home and overseas.

In 1819 John WILLIAMS of Scorrier built a horse drawn railway from his Poldice mines to a newly constructed harbour at Portreath on the north coast. More important was the construction by John TAYLOR of the Redruth and Chacewater Railway linking his mines near St Day to Devoran, a new harbour in the Fal Estuary on the south coast. Although later extended to Carharrack, Lanner and Redruth, the railway never reached Chacewater!

Population growth and distribution

It has been estimated that the population of Gwennap parish had reached 4,594 by 1801, and continued to grow at an accelerating rate until a peak in 1841, when the census recorded 10,794 individuals. Gwennap was by then the most populous of any rural parish in Cornwall and the second of all the county parishes. Madron, which included Penzance town, had only 300 more. There was only a small population decline until 1861, but subsequently many left the parish, leaving only 5,662 by 1901 - slightly over half its peak population.

The early editions of the Ordnance Survey one inch and six inch maps appear, at first, inconsistent with a densely populated parish. Gwennap church town never grew to more than half a dozen buildings around the parish church, and nor did any of medieval St Day, 18th century Chacewater, and the later industrial villages of Lanner and Carharrack, ever grow to more than terraces or cottages along half a dozen or so streets. The explanation was that many of the mining families were dispersed over the parish in often self-built cottages, on small holdings, which they worked as part-time farmers. They might keep a pig and some hens, and rent a cow from a local farmer. A miner might produce sufficient to meet most of his family's food needs. If they changed the mine in which they worked, miners often travelled four or five miles to and from work rather than moving house.

Note: If your relatives came from Lanner village, I strongly recommend "Lanner - A Cornish Mining Parish" by Sharron SCHWARTZ and Roger PARKER. Lanner was part of the civil parish of Gwennap until 1844.

China Clay Mining near St Austell

China clay spoil heaps - Often known as the Cornish Alps. ©John Rostron

This is an entirely different method of mining from the deep copper and tin mines. The deep pits created by the surface excavation of kaolin and the steep hills of waste material extending for approximately 25 square miles to the immediate north of St Austell, form possibly the most distinctive man made landscape in the United Kingdom. Exploitation of the rare type of decomposed granite started as early as 1745, when William COOKWORTHY found a way of using water to filter out impurities from the kaolin, and in the following 20 years developed his own technique for manufacturing porcelain. COOKWORTHY also began to sell the raw material to other English potteries. By the early 1800s St Austell was the largest world producer of kaolin and uses were also being found for the clay in manufacturing paper, paint and rubber products. By the mid 19th century the industry employed 7,000 men, either spraying the walls of the pits with high pressure hoses to remove the clay, or engaged in processing and transporting the material which was being sold worldwide. Unlike other forms of West Country mining the industry was still expanding by 1900 producing, by then, about 50% of the world's china clay. The industry has since dwindled in the face of overseas competition but about 30 china clay ships still dock in Charlestown each year.

I had anticipated that unemployed tin and copper workers would have moved to St Austell in the late 19th century, but a search of my database produces no evidence of this, presumably because experienced deep miners were not attracted by the poor wages and conditions of the St Austell labourers. Instead we find the industry drawing entirely on two long established local families for 55 MORCOM workers: GWENNAPhercules St ENODERwilliam and a few close relations, mainly from St Stephen in Brannel, and the Ladock family PROBUSwilliam PROBUSthomas.

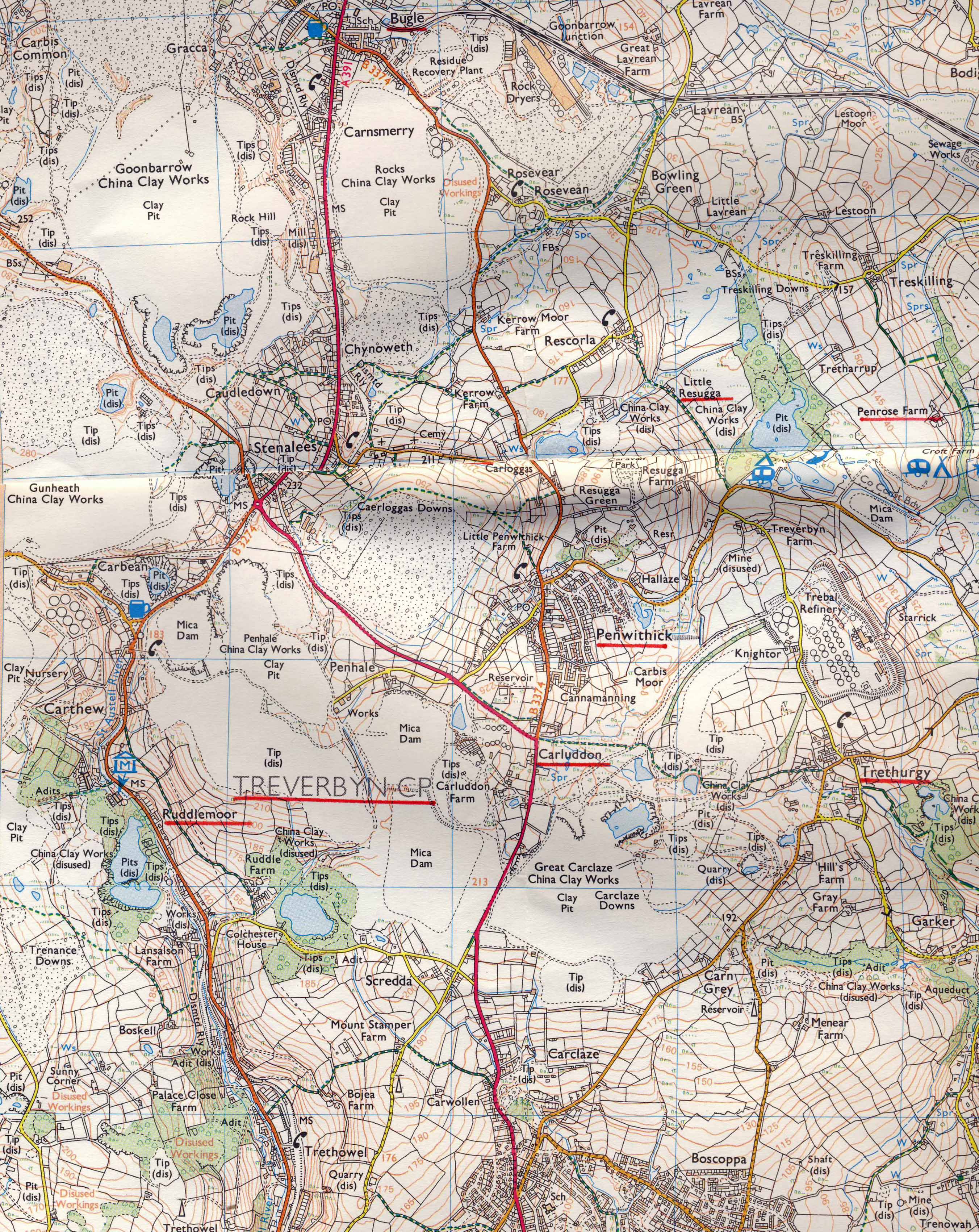

Locations of MORCOM/BE residences underlined in Red. The area covered by the map is approximately 3.2 miles N. to S. and 2.4 miles W. to E. ©Crown Copyright. Reproduced by permission of Ordnance Survey

Employment practices in mining

The tribute system of employment was originally unique to Cornish mining, but was later exported to Cornish mining areas in North America. Mine galleries would be divided into "galleries" and further sub-divided into "pitches", each about 60 ft high and 30ft long. These pitches would be put up for auction, miners, or more often small groups of miners, contracting to break the ore, bring it to the surface and, in some cases, dress it for the market. The mine captains would previously have judged the value of the pitches, and the pitch was then be offered at the "captain's price", which would be low to encourage the purchase and working of poorer pitches, and high for rich seams so that miners would not be excessively remunerated, The sinking of shafts and the driving of shafts was paid for by the fathom. Under the tribute and tut systems the miner had to buy all his blasting powder, cartridges angggjjjd candles at a profitable price for the mining company, and the cost of these would be deducted from the value of the ore the miner produced or the amount of ground he mined. These payment methods, made each miner a small scale entrepreneur. Any attempt to form unions was quickly squashed by the management but, although the bidding process set miner against miner, the tribute and tut systems were generally well liked by the miners, because they allowed them to benefit from their own enterprise, energy and expertise. The men with superior judgement probably earned most, but there was always an element of luck, a good seam dying out, or the converse.

Miners

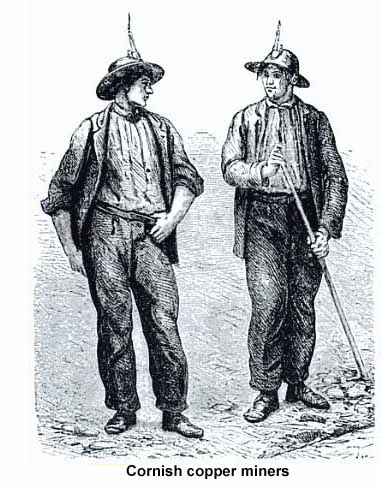

There are no reliable statistics available on the numbers engaged in the Cornish mining industry in the first half of the 19th century but there may have been about 19,000 men and 2,200 women employed c.1825, and by about 1860, 300 mines were employing about 50,000 Cornish men and women. Philip PAYTON estimates that, by 1850, mining directly employed over a third of the working population of Cornwall.

The Cornish Pasty was the traditional meal for Cornish miners underground and is now regarded as the national dish of Cornwll. The pasty should be shaped like a ‘D’ and crimped on one side, not on the top. Its ingredients should include beef, swede, potato and onion, with a light seasoning of salt and pepper, and should keep a chunky texture. The tradition is still kept alive in many regions of the Cornish Diaspora, including many parts of Australia; the Upper Peninsula of Michigan; Mineral Point, Wisconsin; Butte, Montana; and around Scranton, Pennsylvania. The town of Real del Monte, Mexico even has a museum of pasties. Photograph ©David JOHNSON

Working conditions in the mines.

Most men were employed on underground work for six days a week and eight hours a day. It was not unusual for the walk to work to be three to five miles. Their complexions were usually wan and shallow as they would see little of the sun except on Sundays and two or three feast days a year. The best opportunity to get married was sometimes Christmas Day. In the days before steam engines came to their rescue, even reaching the ore seams was arduous and dangerous, involving climbing almost vertical wet, slimy, and often damaged ladders. In the deeper mines men, some with early TB symptoms, might have to climb for an hour continuously to "reach grass" (i.e. the surface). This was particularly hard on older miners, including veteran captains. It was not until the 1840s that the first "man engines" were introduced for transporting men up and down the shafts, In addition the access shaft might be far from the ore face they were extending. Before the days of power drills, the miner's day was mainly spent hammering through the granite at a rate of no more than a foot a day by the light of a single candle. Ventilation was often poor, the air being made worse by the burning of tallow candles, gunpowder fumes from blasting, and the smell of human excrement as there was no sanitary provision. As long as a man was fit to work, mining was well paid compared with most other occupation. Water issuing from the rocks was often uncomfortably hot, and it was said that you could heat up a pasty inside a dinner pail in minutes. When mining was prospering, wages per month varied from as low as £2, to £3-4 for tributers and £8 for engineers. In comparison, a miner who did not own his own house, might pay only £3 a year in rent. it was rare to have insurance against illness, but Gwennap Consolidated and Fowey and Par Consols unusually paid 30s a month sick pay together with medical attention for the miner and his family.

Health and life expectancy

The miners' bodies were usually stunted through crawling on their knees along narrow galleries and labouring in cramped situations. A major cause of ill health was the contrast between the c.80 F heat of the mine galleries, and the often cold gales they had to face on the journey home in the Cornish winter. In addition they might first have to walk a quarter of a mile or so in wet clothing to reach the changing house, though all mines did not have changing facilities. This, combined with the rock dust, resulted in TB, silicosis and other lung infections. Heart conditions were also common at a relatively early age. William Wale TAYLER, surgeon to the Fowey and Par Consols mine, wrote "there is a critical period in a miner's life {40-45 according to TAYLER], when if certain symptoms appear, he should at once discontinue underground labour. But the difficult question is - how shall he obtain sufficient labour above ground to support himself and his family". On the surface he would have to compete for work with very low paid bal maidens and children. Despite this, a miner forced to look for surface work at an early age, because the loss of an arm or leg in a mine accident, might often have a better life expectancy than colleagues who continued working in the galleries. A frequent cause of mine accidents was the unpredictability of blasting with explosives. TAYLER also states that from October 1848 to September 1950 in Tywardreath and St Blazey parishes (where there were several MORCOM families), a quarter of deaths were from consumption, many of the deceased being the children, under one, of miners with TB. In Gwennap the average life of a miner in 1841 was 28, and in Lanner one fifth of the adult population were widows in 1851. It was not only mining which caused a high death rate in Gwennap. Overcrowded accommodation and insanitary conditions, included polluted water supplies, made life in mining areas even more hazardous. Epidemics of cholera, typhoid fever, smallpox and diphtheria were common.

Mine Captains/Agents

The mine captain or agent had the main responsibility for the detailed management and supervision of deep mine operations, and might be responsible for the work of an average of 150 men miners. A large mine might appoint three or four captains for underground work and, maybe, another one or two to be responsible for surface work. They were always chosen from the work force, managers selecting miners who were knowledgeable about mining, intelligent, and well respected by their mining colleagues. Particularly valued were captains who had become, through experience rather than formal training, engineers expert in the installation and maintenance of steam engines in deep mines. The captain's work was very varied and arduous. Their position in the mine was potentially difficult, as they were the intermediaries between management and miners, and often had to enforce unpopular decisions and policies affecting the work force. Their administration of the tribute system of payment had to be accepted as reasonable by both miners and the companies who owned the mines. Above all senior managers expected them to produce good yields of copper or tin at the minimum cost. Despite the difficult diplomacy required in their role, captains or agents were generally well respected by those they managed.

Captains usually wore a distinctive uniform of white drill coats and high pole hats, a combination not well designed for men who might spend two thirds of their day underground. Although the numerous county and local scientific societies, in 19th century Cornwall, valued the engineering and geological expertise of mine captains and, engineers, invitations to join societies, were seldom accepted by the miners. However, in Cornwall and elsewhere, captains were often prominent in religious life (see my ancestor Joseph MORCOM), and overseas often held prominent posts in lodges and, more rarely, were active in politics (see Elisha MORCOM 00189).

Analysis of my database produced some surprising results. There were almost 550 men who were described, mainly in 19th century censuses or other records, as having worked in the industry as miners and/or captains and/or agents, at some time in their careers. MORCOMs were far more frequent in this list than MORCOMBEs, who were in the majority when the same analysis was made of farm workers. The surprising feature was that there were about 50 of these same MORCOMBE men and close relations, who became mine captains or agents at some point in their careers. I can only speculate that this was, at least partly, because the Gwennap/Redruth/Camborne area, where so many MORCOM miners were born, was a centre of technical innovation in deep mining. But, maybe, even more significant was how many of these captains/agents came from just two of the families in our one-name study database. There were 29 mine captains/agents from the St ISSEYjohn family and a further 7 from GWENNAPhercules, the two families including 72% of the captains/agents, despite only totalling 29% of the individuals in the database. Their origins in the Gwennap/Chacewater mining area was obviously one reason for their pre-eminence, but there was also a distinct pattern, especially in the St ISSEYjohn line, of sons and grandsons following a successful captain. One can debate how far inherited intelligence and personality traits, family money, education, the belief in success, and the acquiring of skills through working with older members of a family, contributed to the success of descendants.

Bal maidens

"Bal" was Old Cornish for mine, though replaced during the 18th century by the far more widely used "Wheal". Bal maidens and bal boys were, therefore, those who worked at the mines. Poor wages made it necessary for as many family members as possible to earn, however little, in the mines, and attaining as high a production as possible under the tribute system was an additional incentive for involving women and children in the processing of ore. A father was often killed or incapacitated in the mines, and the widow and her teen-age daughters had little option except to take surface work in the mines while boys, as young as eight, might work underground to earn slightly more money. Most mines gave priority to such impoverished families in allocating work and, in many ways, the mine owners were more considerate of the work force than the factory owners of the time.

The Gwennap Vestry Book of 1836 noted that "Now, from the nature of the miners' occupation, the average duration of male lives is, from accidents and other causes, very materially shortened and, in consequence, the number of widows with young families is very large." Many of our MORCOM families would have been much larger in later generation if mining husbands had survived longer.

The first written evidence about bal maidens was in around 1700, but the practice is almost certainly much older. By 1842 there were over 5,000 women employed on the surface in the Cornish copper, tin, and lead mines. This total included 700 girls under 13, and 1,740 aged 13 to 18. The average age girls started in the mines was 10 or 11, but, in impoverished families, they sometimes started work as young as 7. Consolidated Mines paid the youngest about twelve shillings a month, increasing to eighteen shillings for all over seventeen.

Bal maidens usually worked six days a week, with seldom more than 3 days holidays in the year. Their hours were from 7am or dawn in winter until 5pm or dusk, though sometimes extended, and only half an hour was allowed for lunch. Igggggn addition they often had to walk 3 miles or more to the mine, which meant that it might be dark when they left home and returned. They were usually employed in sorting ore from the waste, breaking down pieces of ore with a flat iron hammer to about half inch wide pieces, and some of the separation process involving washing and sedimentation, as well as fetching and carrying between different processes. The women and oldest girls would do the more arduous tasks, those below about 12 would pick and sort the ore, and young teenagers were most often working on the separation processes. Sometimes the bal maidens worked under crude shelters but often they were in the open in all weathers. Back problems were common, as were rheumatoid problems and lung diseases. Additional health problems affected those working with lead or arsenic, while some mine situations were noisy enough to cause deafness.

Women, girls and young boys were also working in the St Austell china clay industry, while the practice was also found in Devon mines, though the description "bal maiden" was seldom used. Even in the Cornish censuses other terms were often used e.g. "tin dresser", "works at mine", "copper miner", "mine girl" etc. Single women usually continued working as bal maidens until they emigrated, or when they married, which was most often at about 17. It has been suggested that when they married, the women were usually less proficient at domestic work and child caring than those who had remained at home all day. Spinsters, widows and the wives of incapacitated miners might work past middle age.

There were few legal constraints until the Factory and Workshop Act of 1878, which restricted the hours of work for all, and only allowed children under 14 to work part-time. By then many Cornish and West Devon mines had closed, though there were still a few bal maidens employed until mechanization replaced them shortly before Word War I. It was always much less common to find women working at the mines overseas, possibly because the men were generally better paid than in Cornwall.

There is an excellent website called "Bal Maidens and Working Women", and the site included the table (with links) below, which lists the details of 56 MORCOM women. It is important to select the "Detail" for each woman as this reveals information on the census year of the information and how her work is described. Identification in the census is helped by details about her residence and parents, and whether she was single, married or widowed. You will note that the description "bal maiden" is seldom used, the occupation descriptions being very varied. Most of the women are single, and there is a noticeable number where only the mother is present in the census. Most were born and lived in Gwennap or neighbouring areas, including Kea, Kenwyn and Redruth. Some of the information comes from mine records. While the census records of most of these women can be found in my database, I have not yet had time to enter, the often detailed information about occupations, found in the mine books.

"MORCOMs in Balmaiden Database

Media on West Country mining

Film: An Introduction to the Cornwall and West Devon Mining landscape

Note: If you click the bottom right hand corner of the film you can view the video full screen. This film is followed by some amateur videos on Cornish mining. Select the back arrow in the top left corner of the screen when you are ready to return to the web site text.

Early Flash Photographs of Cornish Tin Miners Underground taken by J.C. BURROWS in the 1890s

To the next section - Early Morcom/be locations and movements in the West Country

OR Back to - Main menu